Do I Need A Router Template Guide

Making & Using Router Templates

Past: Ted Raife

When it comes to making odd-shaped or identical parts for your projects, a router and a template will assist you get loftier-quality results.

It'south difficult to overestimate the value of a router in the workshop. Frequently, the tasks you can perform in seconds with a router would accept much longer with any other tool. And one way to get the near out of your router is to use it for making perfect duplicate or mating parts for a project. Usually this involves working with a template.

You might already be familiar with the thought of template routing from using a dovetail jig. In this awarding, a router equipped with a guide bushing follows the fingers of a dovetail template to cut perfectly spaced, tightfitting dovetails in minutes. This same concept opens up a lot of possibilities for creating matching inlays. Once you learn to make pieces, tight-fitting joints, or seam your own templates and choose the right router bit for the chore at manus, in that location are almost no limits.

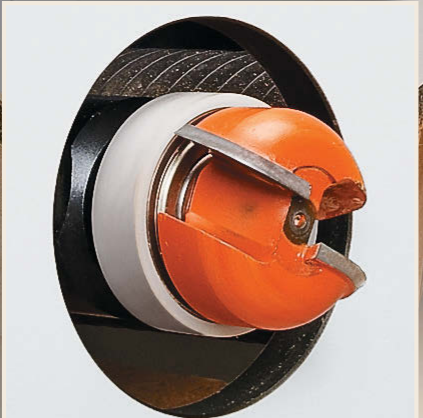

SELECTING ROUTER $.25. Chances are, you already have at least one of the most common template routing $.25. A flush trim bit, similar one shown in the photo above, is the perfect pick for templates designed to fit beneath the workpiece. With a bearing at the tip riding against the template, a affluent trim bit levels the edge of the workpiece to match.

This same combination works in a router tabular array too. Only at the router table, you tin take the template on acme of the workpiece instead of below. A good example of this is routing matching top rails for "tombstone" cabinet doors.

But in some instances, when using a template with a hand-held router, you'll need to attach the template to the top of the workpiece. For this situation yous have a couple of options. Unremarkably, I turn to a pattern chip, also shown in the photo in a higher place.

Often mistakenly chosen a affluent trim bit, a pattern scrap has the bearing on the shank of the bit instead of at the tip. This allows yous to secure a template on pinnacle of a workpiece and clench them both to your bench to rout the shape. And pattern-style $.25 aren't limited to directly cutters. The bowl-routing scrap shown below is simply a different profile with a bearing on the shank to follow a template.

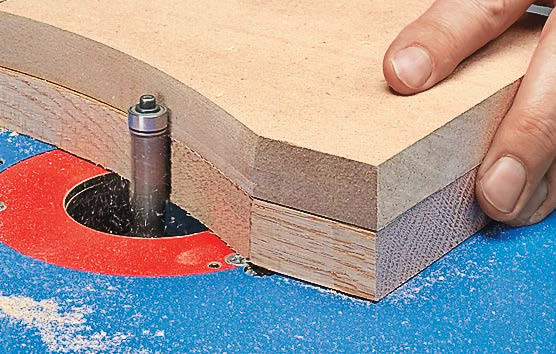

GUIDE BUSHINGS. The other way to rout a pattern from above the workpiece is to use a guide bushing. The bushing locks into the hole in the baseplate of your router to follow a template. Bushings are available in several different diameters so you can employ a variety of router bits with them. (You lot can see an example of a guide bushing in the router inlay kit shown in the box below.)

The thing to keep in mind when using a guide bushing is that it will create an offset between the template and the workpiece. This ways yous'll need to account for the distance from the edge of the bushing to the cutting edge of the fleck in your template design.

MAKING TEMPLATES. With a pattern and the right bit in heed, all that remains is to make a template. In that location are commercially made templates for all kinds of tasks and patterns. But it's worth taking the time to learn how to brand your ain, not just to salve money only to accommodate the designs of your ain projects. And it's non a difficult skill to master.

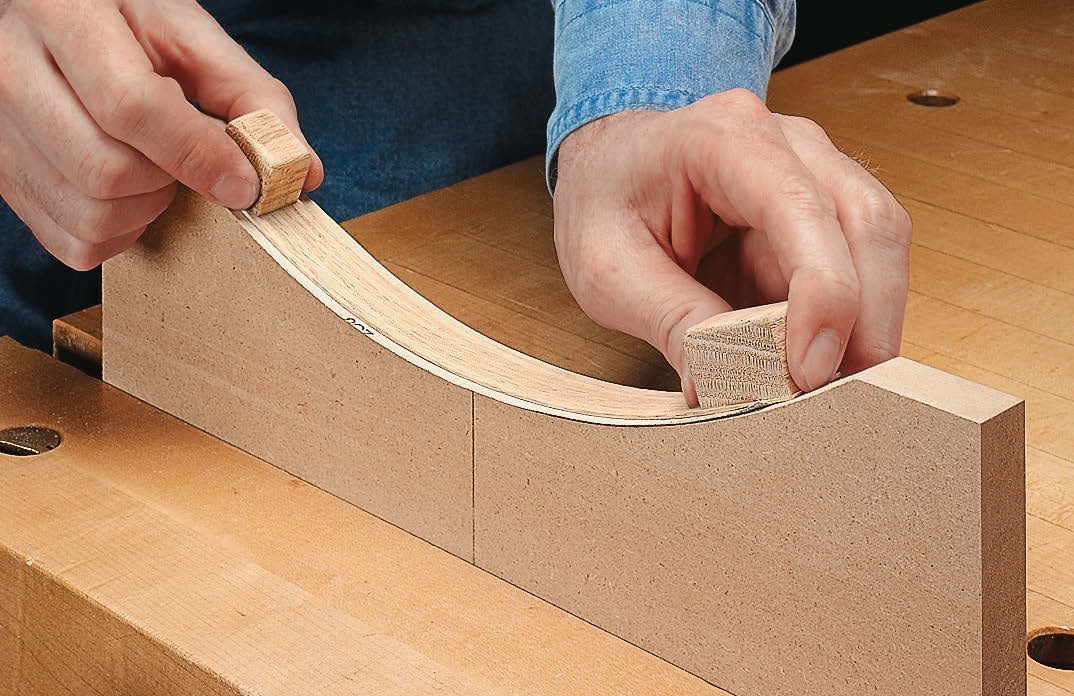

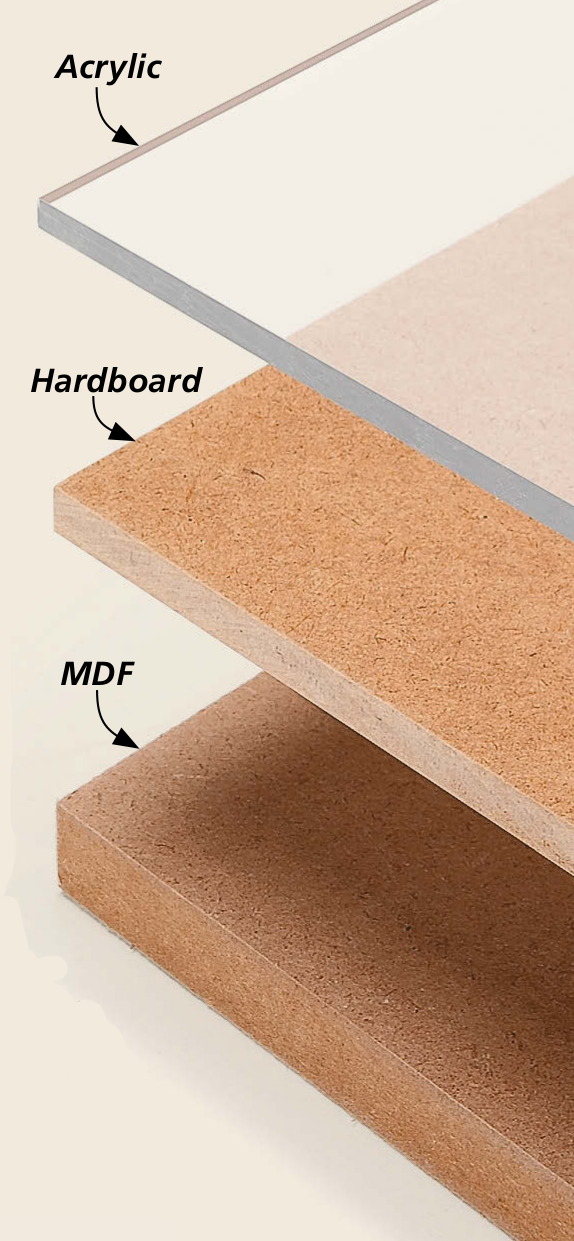

MDF. Templates can be fabricated from many kinds of material. MDF is a readily bachelor pick, and it'south usually my first selection.

The reason I prefer MDF is that information technology's perfectly flat and very easy to shape with files and sandpaper. The template I employ for making curved rails for cabinet doors shown in the photograph to a higher place is a good instance. To brand information technology, I only laid out the bend with a compass, cut out the shape at the band saw, and smoothed the curve, first with a file then with a elementary, shop-made sanding strip, seen beneath.

OTHER OPTIONS. Hardboard is another usually used material. And occasionally I use acrylic, particularly for those applications where I need to see more of the workpiece to orient the template to the grain of the wood.

On the other hand, a template can be as simple as minor pieces of hardwood joined with pocket screws. This is an easy technique for making a template that conforms to a rectangular shape. All you need to do is fit the pieces together to form a template with the within dimensions equal to the desired size and spike them together.

With a little imagination, you tin can make a template for just most any shape you need for your projects. Whatsoever the application, you'll find that learning to make and use templates with your router will guarantee superlative-notch results.

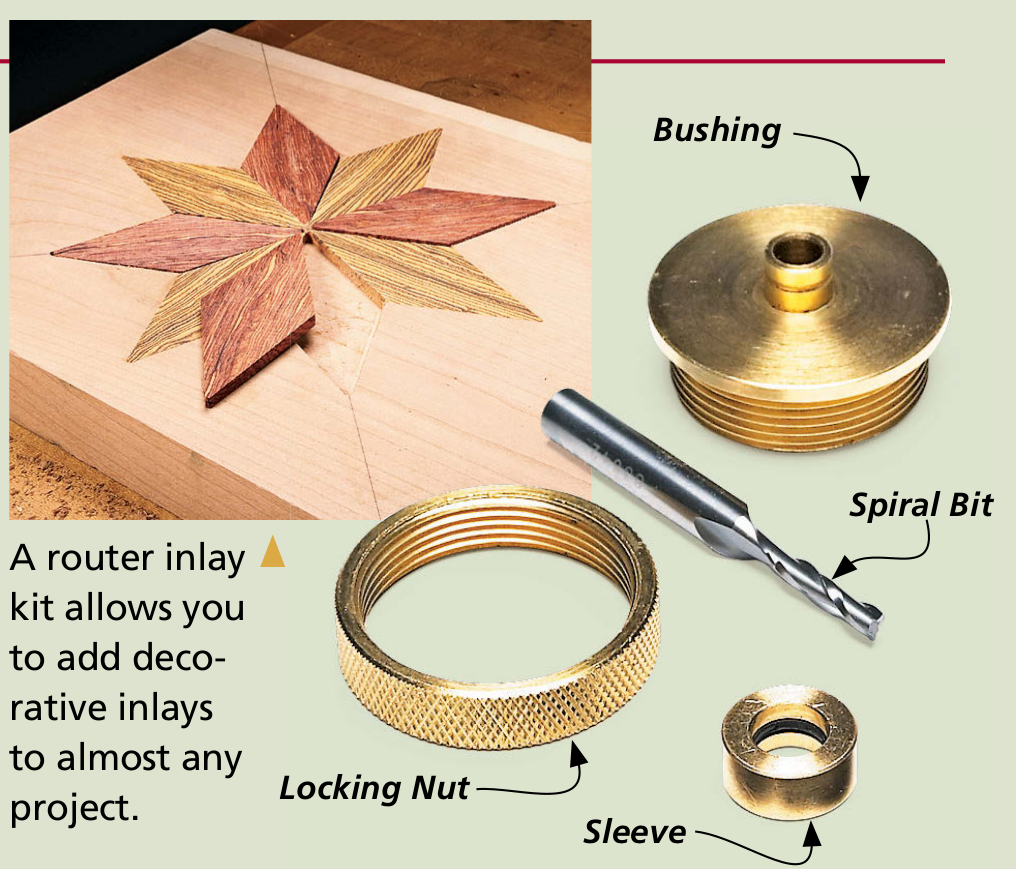

Worth a Look: Router Inlay Kit

One of my favorite ways to spice up a project is to add together a decorative inlay fabricated from contrasting forest. A specialized guide bushing with a removable sleeve makes this an easy operation. With the bushing installed, you can cut both the recess and the inlay piece using a single template.

ROUTING THE RECESS. After selecting a template for your design, start by positioning the template on the workpiece and securing it with double-sided record. And so, with the sleeve on the bushing, but rout the outline of the recess and the remainder of the waste by following the template. If necessary, foursquare up the corners with a chisel.

THE INLAY. Now you lot tin can attach the template to the stock you lot've chosen for the inlay. Afterward removing the sleeve, only rout the outline of the inlay and lift the router. Free the inlay from the lath by resawing the piece at the ring saw. With just a piddling practice, y'all can make perfect-fitting inlays in no time.

Do I Need A Router Template Guide,

Source: https://www.woodsmith.com/article/making-using-router-templates/

Posted by: mcdonaldjaclut36.blogspot.com

0 Response to "Do I Need A Router Template Guide"

Post a Comment